|

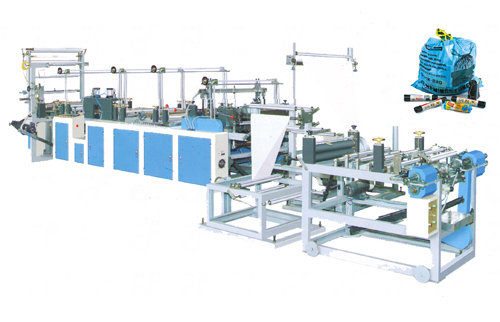

Computer-controlled ribbon-through Garbage Bag Machine

1.Characteristics

Designed and developed by assimilating the foreign technologies, this machine adopts LDPE/HDPE as raw materials to make ribbon-through garbage bag or BOPP/PP flat-open bag, It is featured with computer control, photocell tracking,auto temperature control,auto counting and alarming, Meanwhile, it can also finish edge-folding,mouth-forming, ribbon-through and perforating at one step,which guarantees that firm,regular and nice continuous-winding bags.with optional functions like multi-folding and dotting, it is and ideal supporting equipment for bag making machines.

2.Main Technical Parameters.

brief introduction:

the machie is an new product,devoloed and improved by our company on the basis of advanced technology both at domestic and overseas.Edge-cutting and edge-folding can be finished by a time.Temperature controller,perforation,draw tape,hot edge-sealing from up and down,photo-electric tracking,dot-servering.hot bottom-sealing and automatic counting.besides it can cooperate with fokding machine and roll-connection machine.Featured by full-automatic and high quality and also can be an investment income.The machine set is suitable for high-density polythylene.Low density polyethylene plastic film bag maker.

| Model |

MK-G1000 |

MK-G1300 |

| Sealing and cutting width |

730mm |

730mm |

| sealing and cutting length |

1000mm |

1300mm |

| bag-making quantity |

1PC |

1PC |

| Thickness of product |

0.015--0.05mm |

0.015-0.05mm |

| Bag-making speed |

10--40pcs/min |

10-40pcs/min |

| Motor Power |

2.2kw |

3kw |

| Machine Weight |

1700kg |

1800kg |

| Overall Dimensions (LĂ—WĂ—H) |

14000Ă—1900Ă—2000mm |

14000Ă—2100Ă—2000mm |

|